Injection Moulded Plastics

Gulf specialises in engineered plastic components for critical applications that demand tight tolerances, reliable quality control, and long term production repeatability. We offer an extensive range of products across the automotive, industrial, agriculture, tapware, and general potable and non-potable water industries.

Enquire Now EXPLOREOverview

We offer an extensive range of products across the automotive, industrial, agriculture, tapware, and general potable and non-potable water industries.

Plastic injection moulding has many benefits for numerous companies in various industries. Principally, these are the ability to manufacture parts quickly and in high volumes, and to do this with consistency of features and the same high quality. At the other end of the scale, it’s feasible to produce very low volumes of highly technical products, often in the form of prototypes. Read more

Benefits

In-house toolmaking

Rapid prototyping

Quality Assurance

Material expertise

Customised design offering

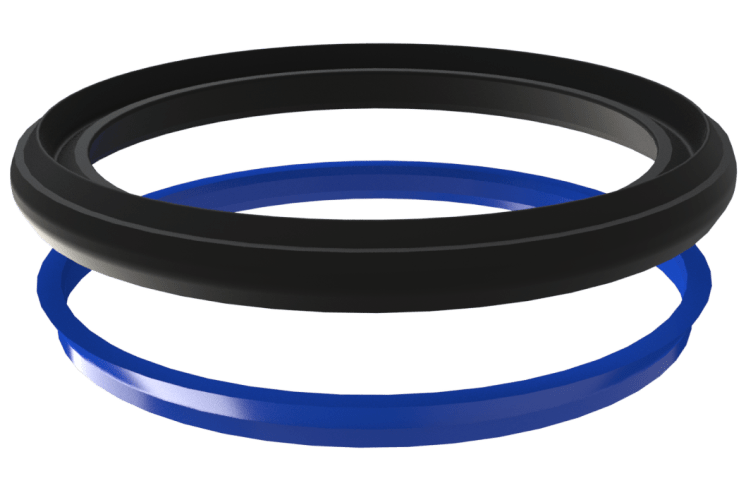

Range

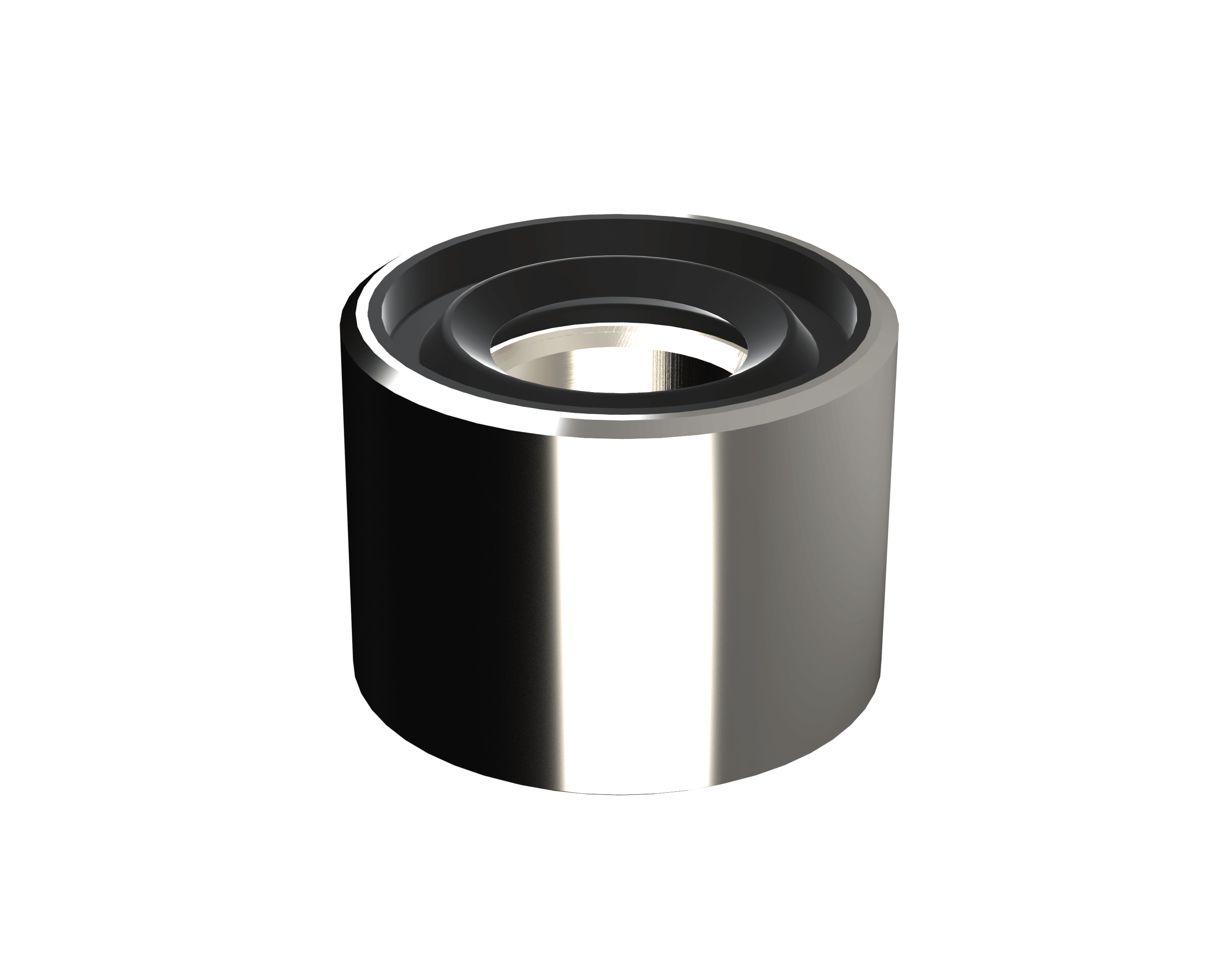

Centering Bush

Critical OEM component used to center and maintain radial position of the vehicle propshaft.

Injection Moulding in Australia

In recent years, injection moulding has become increasingly popular in the engineering and component parts industry. It is a simple process with great versatility and offers a superior quality finish. Most people think that injection mouldings are exclusively for plastic. However, many materials can be used in an injection process, including metals and glass. The roots of this process go back to 1872 and the first applications were for the production of buttons and hair combs.

Today, the process involves plastic granules, being heated and then forced into a mould to mass produce, high-quality copies of the required part. Most plastics we use today go through a injection moulding process. It is a very common process.

Are you Searching for Custom Injection Moulding Plastics?

If you have found yourself on this page because you are looking for a company to design and manufacture plastic or rubber parts, then you have found the right page. Gulf Rubber is a leading authority on plastic mould injection in Australia. You will have observed by now that there aren’t any companies better placed or capable of attending to your custom plastic injection moulding project. Our client base is a mixture of repeat and one-off customers. Some require a full in-depth service because they are on unknown territory, whilst others can maybe attend to some components of the production process. No matter what your circumstances, we create bespoke packages of service depending on the extent of your needs.

Injection Moulding Services Australia

Gulf Rubber offers a range of services established over many years, based on our experience of the needs of different market sectors. In the main, however, most of our clients require a concept to delivery service encompassing all aspects of injection moulding services in Australia. Australia boasts some excellent facilities and is geographically close to major production sites in Asia so it’s easy to find us anywhere in your local area:

The second area is our quality assurance status, operating under ISO 9001 accreditation and IATF 16949 standards. We also have sub-levels of quality checking through our Statistical Process Control (SPC) and Process Failure Mode Effects Analysis (PFMEA). The third area is our dedication to high-grade customer service. We operate on the principle of being in partnership with our clients, focussing on teamwork and open book problem-solving processes.

Make Contact and Notice the Difference

We are sure that from the very first conversation, you will find Gulf Rubber the sort of company you will want to work with. Very few people who come to us looking for custom injection moulding plastics walk away having found something better, elsewhere. It simply doesn’t happen. If you would like to take advantage of an obligation-free strategic review with our engineers then please get in touch. Call us on contact form and one of the team will get back to you.

Custom Design Capability

At Gulf, We believe there are three areas of consideration for any potential client to review; The first is that we offer a reliable process, calling on the influence of being part of a wider group of global companies. We operate with precision and predictability. Staying on project timelines and closing within agreed budgets.

Quality Assurance

It’s our goal to ensure you never experience production downtime, expensive repairs, or frustrating warranty claims. That’s why all Gulf factories around the world, and all third-party factories that supply to Gulf, meet the quality standards required for ISO 9001 or IATF 16949.

Our products are manufactured to precise specifications with tight tolerances. When you partner with Gulf, you can have complete peace of mind knowing you will always receive the highest quality components.

Related Products

Searching for the right partner to solve your problem?

Book a consultation with our engineering team

Since 1980, Gulf Rubber’s specialised rubber and plastic engineers have designed bespoke, technical solutions for our partners across the globe. If you have a problem you can’t solve, a concept you can’t pinpoint, or a fragmented process you wish to simplify, we can help.

We’ll get to know your product and application, design a new solution, and use our experience to improve your business outcomes.