With over 40 years experience, Gulf is a leading manufacturer of precision engineered rubber and plastic components. With extensive Industry experience across a range of products and sectors, Gulf has the expertise and know-how to solve your problems.

Rubber Engineering Services

If you are searching for a company to handle the production of your bespoke rubber components, then you will want to know more about Gulf Rubber Australia (GRA). As rubber engineering specialists we take concepts to delivery in a cost-effective and timely way. Often described as innovative by our clients, we have a 40-year track record of producing high-quality rubber components across a large spectrum of industries. We have an experienced and highly competent team spread across many disciplines, including rubber chemists, quality managers and mechanical engineers. Read More

We work with you - from concept to reality

CONSULT

We listen to your

challenges and objectives

Help you understand what’s realistic and unrealtistic

DESIGN

We prepare a

series of concept

designs

ENGINEERING

DESIGN

Provide detailed

drawings

for final approval

Provide a costing

PROTOTYPING

Test materials and

manufacturing

Formulate compounds

Produce the samples

Provide a detailed

dimensional report for

approval

CUSTOMER

APPROVAL

Approval of

samples

PRODUCTION

Regular and

timely supply

Benefits / Capabilities

- Consultative partnership approach

- Unique Material science expertise

- Global Material Approvals

- 3D Modelling and Rapid Prototyping

- Simulation, FEM & DFMEA Analysis

- Product and Industry expertise

Key clients

Our focus areas

Partnership approach

We believe that investing in partnerships is the best way to achieve results. We take a collaborative approach to product development, and start by understanding your needs and then continue to work in close collaboration throughout.

We work with you to intrinsically understand your business, products, and challenges, and utilise our capabilities to find solutions.

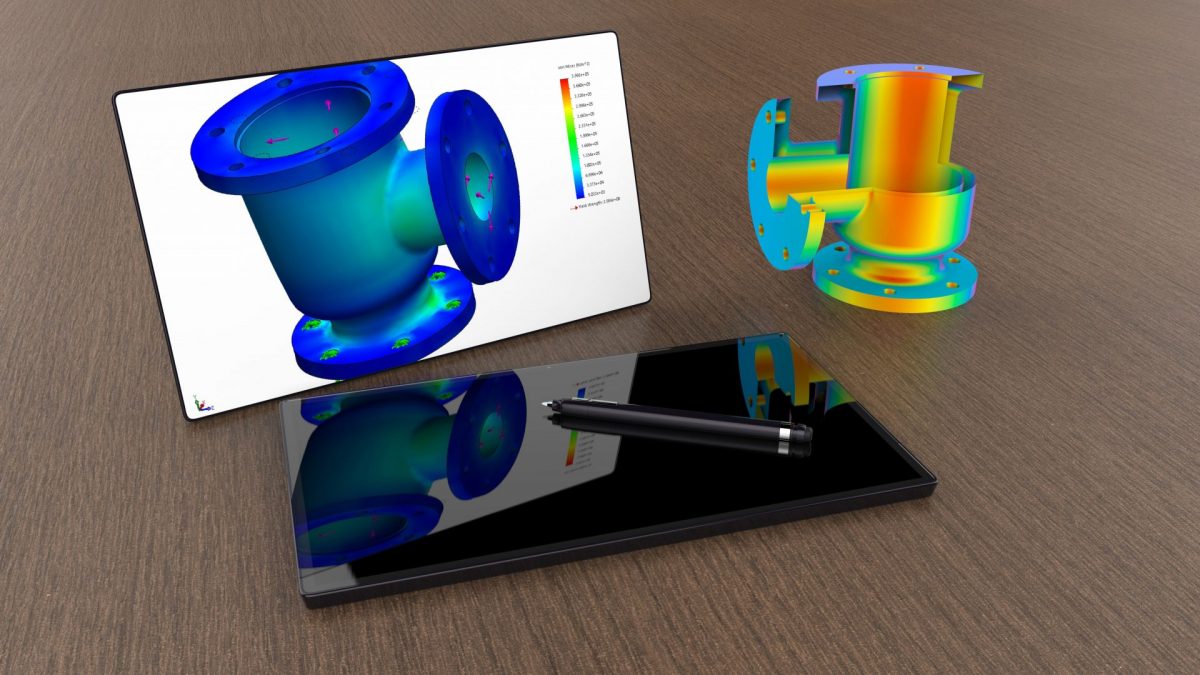

Simulation and Rapid Prototyping

Here at Gulf we understand the product development challenges, and costs associated with design revisions and project delays. That’s why we use cutting edge technology to optimise, simulate, and streamline our development processes.

ACAD, SolidWorks Simulation, FEM, DFMEA, Stress Analysis, life expectancy in fatigue, dynamic metal forming and sealing optimization, are just a few of our programmed engineering strategies.

With the in-house capability for rapid prototyping, combined with our simulated development processes, Gulf is market leading.

Integrated components and inter-material bonding

Working with rubber, plastics, metals and ceramics, our experts craft materials with incredible toughness, durability and greater reliability. We are experts at bonding rubber to a range of material substrates, such as plastics, metal and fabric.

As specialists in integrating components, we can supply you with complete sub-assemblies, simplifying your products, and streamlining your supply chains.

Rubber Engineering Services in Australia

In addition, we have a focus on research and development, utilising cutting-edge technology, ran through certified testing laboratories for all the best products such as our rubber o-ring seals and industrial gasket supplies.

Quality Processes – Ensuring we Offer the Best Australian Rubber Engineering Services

To establish and maintain exemplary quality in all corners of our business, we default to standardised procedures with failsafe and self-checking mechanisms to ensure a top-grade end product is constantly produced. In analysis, we use Design of Experiments (DoE), Failure Modes and Effects Analysis (FMEA) and Finite Element Analysis (FEA). We also have first-rate expertise in the building of testings rigs, essential for product certification. We also offer prototype tooling, a fast and less expensive and more analytical route toward production tooling.

With current experience going back over 25 years, the team there at Gulf have seen everything and been at the helm of designing new products for applications subject to heat and fluid ageing. Engineering services for rubber components can leave no area of production untested. At Gulf we are thorough and complete in our design and analysis, bringing a quality final product that incorporates all current technology and scientific application.

Partnering with GRA for the Best Rubber Engineering Specialists

Once commissioned to a design and production project, Gulf’s full-service offering comes into effect, with many hidden benefits. For example, we are specialists in integrating components and can create complete sub-assemblies if required. We recommend this, if applicable to help streamline the production process and reduce the complexity of the supply chain.

We feel that by now if you are still reading this you will be close to getting in touch to discuss your needs and project aspirations. Before you do, we need to re-assure you about our quality control processes. Quality is part of everything we do. We practise recognised process controls such as Statistical Process Control (SPC) and Process Failure Mode Effects Analysis (PFMEA). We are also a Proven Zero-Defect rubber manufacturer in Australia, meaning we work to systems that show a zero-defect status on everything we manufacture from check valves to injection moulding in Australia are met to this standard. All Gulf Rubber factories around the world, including our third-party suppliers, meet the quality standards required for ISO 9001 or IATF 16949.

Start a Strategic Review Today

We are convinced that by now, you will be thinking that Gulf could be your partner for rubber engineering services in Australia. Experience has shown us that the best first step is for a strategic review of needs. This can be a telephone call or a meeting in person or online. Please call us on contact form and one of the team will get back to you.

Quality Assurance

We are a proven zero defect manufacturer working with tight tolerances, our products are manufactured to precise specifications. Our components are used in critical applications where failure can have catastrophic consequences, and we make absolutely sure quality is built into everything we do.

At Gulf, we are committed to Quality. All Gulf factories globally, and all third-party supply chain partners meet the quality standards required for ISO 9001 and or TS 16949. When it comes to working with precision engineered rubber and plastics, our quality is unmatched.

Quality Assurance

It’s our goal to ensure you never experience production downtime, expensive repairs, or frustrating warranty claims. That’s why all Gulf factories around the world, and all third-party factories that supply to Gulf, meet the quality standards required for ISO 9001 or IATF 16949.

Our products are manufactured to precise specifications with tight tolerances. When you partner with Gulf, you can have complete peace of mind knowing you will always receive the highest quality components.

Custom Design Capability

At Gulf, we thrive on the opportunity to innovate. If you need a custom product or solution, then our trusted engineers, chemists, and technologists will work tirelessly to deliver above and beyond your expectations. Whatever your specifications or requirements, you can rest easy knowing that you’ve got the strategic partner who can solve the problem.

Searching for the right partner to solve your problem?

Book a consultation with our engineering team

Since 1980, Gulf Rubber’s specialised rubber and plastic engineers have designed bespoke, technical solutions for our partners across the globe. If you have a problem you can’t solve, a concept you can’t pinpoint, or a fragmented process you wish to simplify, we can help.

We’ll get to know your product and application, design a new solution, and use our experience to improve your business outcomes.